The MMM Lab received a first-place award in the National Institute for Standards and Technology (NIST) Additive Manufacturing Benchmark Test Series, a competition that enables teams to test their simulations against additive manufacturing benchmark test data.

The team included graduate students Carter Cocke, Brian Phung, Laura Ziegler, Elliott Marsden, and Vignesh Babu Rao.

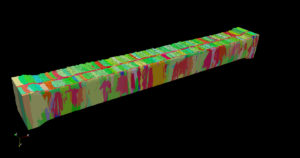

In the team’s specific challenge, titled “Subcontinuum Mesoscale Tensile Test,” all the competing teams were given a set of materials characterization data for a small sample of 3D-printed Inconel 625, a type of nickel alloy. They were then asked to make blind predictions of the mechanical (stress-strain) response of the sample under tensile loading without any other knowledge of the mechanical behavior of the material.

The MMM Lab used a modeling technique that allows it to represent the 3D material structure resolved to very small length scales, and it focused on calibrating the material parameters that go into the model. The model allows them to predict how damage evolves and eventually leads to fracture of a given specimen. The team competed against six other groups from around the world.

The MMM Lab used a modeling technique that allows it to represent the 3D material structure resolved to very small length scales, and it focused on calibrating the material parameters that go into the model. The model allows them to predict how damage evolves and eventually leads to fracture of a given specimen. The team competed against six other groups from around the world.

The awards were presented during an AM Bench 2022 ceremony held on August 17 at the AM Bench 2022 conference in Washington D.C.

This is the second modeling challenge the MMM Lab has won related to predicting micromechanical behavior of 3D printed metal. The other competition was hosted by the Air Force Research Lab and America Makes in 2020.