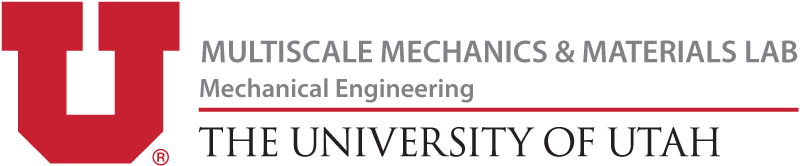

Overview: It's an exciting time in the world of 3D printing! In particular, there is growing interest among the defense, aerospace, energy, and biomedical industries to produce real structural components using metal additive manufacturing (AM), allowing for the production of intricate structural geometries that would otherwise be impossible to produce using conventional subtractive processes. However, there remain many fundamental questions regarding how the printing choices ultimately impact the material microstructure and mechanical performance of a given part. For example, how can we guarantee that parts coming directly off the print bed meet certification criteria to be used in airplanes or in the human body? In the MMM Lab, we bring to bear the power of our numerical tools and experimental observations to study the complex relationships between process parameters, resulting material microstructure (for example, void defects and grain structure), and deformation and failure mechanisms. Our group has participated in (and won) several international modeling challenges involving 3D-printed metals. Additionally, Prof. Spear led the acquisition of the University of Utah's first laser powder bed fusion machine, which we leverage to support our research.

Select publications (MMM Lab members are underscored):

- W. Tan & A.D. Spear, Multiphysics Modeling Framework to Predict Process-Microstructure-Property Relationship in Fusion-Based Metal Additive Manufacturing, Accounts of Materials Research, Vol. 5(1), pp. 10-21, 2024. https://doi.org/10.1021/accountsmr.3c00108

- D.S. Watring, J.T. Benzing, O.L. Kafka, L.-.A Liew, N.H. Moser, J. Erickson, N. Hrabe, A.D. Spear. Evaluation of a Modified Void Descriptor Function to Uniquely Characterize Pore Networks and Predict Fracture-Related Properties in Additively Manufactured Metals, Acta Materialia, Vol. 223, pp. 117464, 2022. https://doi.org/10.1016/j.actamat.2021.117464

- L. Wiesent, A.D. Spear, A. Nonn. Computational Analysis of the Effects of Geometric Irregularities on the Interaction of an Additively Manufactured 316L Stainless Steel Stent and a Coronary Artery, Journal of the Mechanical Behavior of Biomedical Materials, Vol. 125, pp. 104878, 2022. https://doi.org/10.1016/j.jmbbm.2021.104878

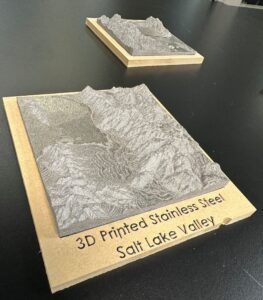

A 3D-printed replica of the Salt Lake Valley. Medium: stainless steel. - C. Cocke, A.D. Rollett, R.A. Lebensohn, A.D. Spear. The AFRL Additive Manufacturing Modeling Challenge: Predicting Micromechanical Fields in AM IN625 Using an FFT-Based Method with Direct Input from a 3D Microstructural Image, Integrating Materials and Manufacturing Innovation, 2021. https://doi.org/10.1007/s40192-021-00211-w

- N. Kouraytem, X. Li, W. Tan, B. Kappes, A.D. Spear. Modeling Process-structure-property Relationships in Metal Additive Manufacturing: A Review of Physics-driven versus Data-driven Approaches, Journal of Physics: Materials, 2021. doi.org/10.1088/2515-7639/abca7b

- D. S. Watring, J.T. Benzing, N. Hrabe, A.D. Spear. Effects of Laser-energy Density and Build Orientation on the Structure-Property Relationships in As-built Inconel 718 Manufactured by Laser Powder Bed Fusion, Additive Manufacturing, Vol. 36, pp. 101425, 2020. doi.org/10.1016/j.addma.2020.101425

- C. Herriott, A.D. Spear. Predicting Microstructure-dependent Mechanical Properties in Additively Manufactured Metals with Machine- and Deep-learning Methods, Computational Materials Science, Vol. 175, pp. 109599, 2020. doi.org/10.1016/j.commatsci.2020.109599

- C. Herriott, X. Li, N. Kouraytem, V. Tari, W. Tan, B. Anglin, A.D. Rollett, A.D. Spear. A Multi-scale, Multi-physics Modeling Framework to Predict Spatial Variation of Properties in Additive-Manufactured Metals, Modelling and Simulation in Materials Science and Engineering, Vol. 27, pp. 025009, 2019. doi:10.1088/1361-651X/aaf753

- S. L.B. Kramer, B.L. Boyce, A. Jones, A. Mostafa, B. Ravaji, T. Tancogne-Dejean, C. Roth, M. G. Bandpay, K. Pack, J.T. Foster, M. Behzadinasab, J. Sobotka, J.M. McFarland, J. Stein, A.D. Spear, et al. The Third Sandia Fracture Challenge: Predictions of Ductile Fracture in Additively Manufactured Metal, International Journal of Fracture, Vol. 218(1-2), pp. 5-61, 2019. doi.org/10.1007/s10704-019-00361-1