Overview: In general, observations made on the visible surface of a structure tell an incomplete story of the structure's response to external stimuli. If we had the ability to see the world through X-ray lenses, our understanding of why structures behave the way they do would be infinitely improved.

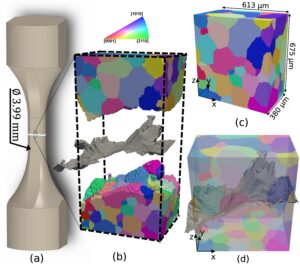

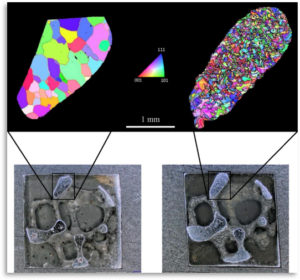

In the MMM Lab, we do just that by leveraging the most advanced materials characterization techniques available. For example, we use high-resolution X-ray computed tomography (XCT) to see how pore defects impact the deformation and failure response of structural materials. We also use a technique called high-energy X-ray diffraction microscopy (HEDM)--available at just a handful of synchrotron sources in the world--to characterize the 3D grain structure of real materials and understand how the grain structure influences mechanical response, including fatigue and fracture behavior. Using HEDM in conjunction with computational simulations, our group pioneered the study of 3D grain structure effect on mechanical response of open-cell metal foams. Some examples of our pioneering work involving advanced 3D materials characterization are shown below.

Select publications (MMM Lab members are underscored):

- A. Greeley, J.F. Adams, P. Kenesei, A.D. Spear, J.E. Allison, Quantitative Analysis of Three-dimensional Fatigue Crack Path Selection in Mg Alloy WE43 Using High Energy X-ray Diffraction Microscopy, Fatigue & Fracture of Engineering Materials & Structures, 2024. https://doi.org/10.1111/ffe.14217

- Q.C. Johnson, P. Kenesei, S. Petruzza, J.C. Plumb, H. Sharma, J.-S. Park, E. Marsden, K. Matheson, M.W. Czabaj, A.D. Spear, Mapping 3D Grain and Precipitate Structure during In Situ Mechanical Testing of Open-cell Metal Foam using Micro-computed Tomography and High-energy X-ray Diffraction Microscopy, Materials Characterization, Vol. 195, pp. 112477, 2023. https://doi.org/10.1016/j.matchar.2022.112477

- D.S. Watring, J.T. Benzing, O.L. Kafka, L.-.A Liew, N.H. Moser, J. Erickson, N. Hrabe, A.D. Spear. Evaluation of a Modified Void Descriptor Function to Uniquely Characterize Pore Networks and Predict Fracture-Related Properties in Additively Manufactured Metals, Acta Materialia, Vol. 223, pp. 117464, 2022. https://doi.org/10.1016/j.actamat.2021.117464

- S. Petruzza, A. Gyulassy, S. Leventhal, J.J. Baglino, M. Czabaj, A.D. Spear, V. Pascucci. High-throughput Feature Extraction for Measuring Attributes of Deforming Open-cell Foams, IEEE Transactions on Visualization and Computer Graphics, Vol. 2(1), pp. 140-150, 2020. doi.org/10.1109/TVCG.2019.2934620

- J. Plumb, J. Lind, J. Tucker, R. Kelley, A.D. Spear. Three-dimensional Grain Mapping of Open-cell Metallic Foam by Integrating Synthetic Data with Experimental Data from High-energy X-ray Diffraction Microscopy, Materials Characterization, Vol. 144, pp. 448-460, 2018. doi:10.1016/j.matchar.2018.07.031

- K. Matheson, K. Cross, M. Nowell, A.D. Spear. A Multiscale Comparison of Stochastic Open-Cell Aluminum Foam Produced Via Conventional and Additive-manufacturing Routes, Materials Science & Engineering: A, Vol. 707, pp. 181-192, 2017. doi:10.1016/j.msea.2017.08.102

- A.D. Spear, S.F. Li, J.F. Lind, R.M. Suter. A.R. Ingraffea, Three-Dimensional Characterization of Microstructurally Small Fatigue-Crack Evolution Using Quantitative Fractography Combined with Post-Mortem X-Ray Tomography and High-Energy X-Ray Diffraction Microscopy, Acta Materialia, Vol. 76, pp. 413-424, 2014. doi:10.1016/j.actamat.2014.05.021