Abstract: Infant skull fractures are common in both accidental and abusive head trauma, but identifying the cause of injury may be challenging without adequate evidence. To better understand the mechanics of infant skull fracture and identify environmental variables that lead to certain skull fracture patterns, we developed an innovative computational framework that utilizes linear elastic fracture mechanics theory to predict skull fracture as a first step to study this problem. The finite-element method and adaptive-remeshing technique were employed to simulate high-fidelity, geometrically explicit crack propagation in an infant skull following impact. In the framework, three modes of stress intensity...

Continue readingMMM Lab represents at TMS annual meeting

MMM Lab members recently presented work at the TMS Annual Meeting in San Diego, CA. The following presentations included MMM Lab members: Determination of Representative Volume Elements for Small Cracks in Heterogeneous Domains via Convolutional Neural Networks: Karen DeMille, Ashley Spear Predicting Crack Location Using a Radial Distribution Function as a Unique Descriptor of Pore Networks: John Erickson, Aowabin Rahman, Ashley Spear Characterization of Fatigue Short Crack Growth in Rare-earth Magnesium Alloy WE43 using High Energy X-ray Diffraction Microscopy: Duncan Greeley (Univ. of Michigan), Jacob Adams (Univ. of Michigan), Peter Kenesei (Argonne National Laboratory), Ashley Spear, John Allison (Univ. of...

Continue readingFive talks at ASME IMECE

MMM Lab members (Dr. Nadia Kouraytem, Dillon Watring, Karen DeMille, Jimmy He, and Jiawei Yan) presented their recent research results at the ASME International Mechanical Engineering Congress & Exposition (IMECE) held in our hometown, Salt Lake City. Prof. Spear also sat on a panel aimed at helping new and aspiring faculty members. ...

Continue readingSeminar at Georgia Tech

Prof. Spear presented work from the MMM Lab in the School of Aerospace Engineering at Georgia Tech on October 17. The talk was entitled Predicting Microstructure-Sensitive Mechanical Behavior of Materials by Integrating Physics-Based Modeling with Machine Learning. The presentation covered research by lab members Kyle Pierson, Aowabin Rahman, and Carl Herriott. Many thanks to the wonderful faculty and students from Georgia Tech AE for fruitful discussions and for attending the seminar!...

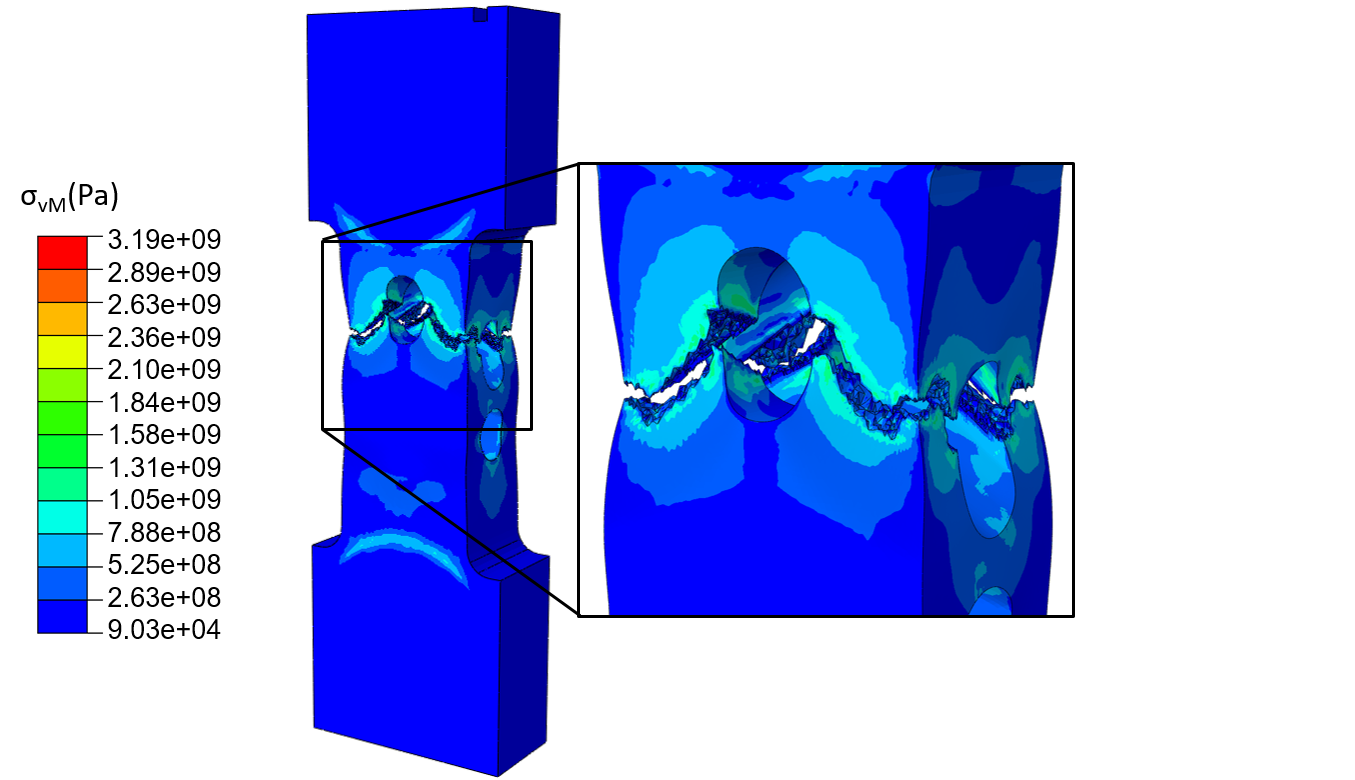

Continue readingClass of 20 Students Participates in the Sandia Fracture Challenge

A recent article in the International Journal of Fracture details the results and experience of a class’ participation in the Third Sandia Fracture Challenge (SFC3). In the spring semester of 2017, 20 University of Utah graduate students who were enrolled in a course on Fatigue and Fracture Mechanics (offered by Prof. Ashley Spear) participated in the Challenge, in which all participants were tasked with predicting ductile fracture in a 3D-printed stainless steel specimen geometry. The participants were provided with data from Sandia National Labs to help calibrate their models and were asked to provide local and global measures from...

Continue readingEffect of build conditions on fatigue properties of AM IN718

Ph.D. student, Dillon Watring, recently published his work on the effect of additive manufacturing parameters on the fatigue-driving mechanisms in AM IN718. Dillon and his collaborators found that build orientation is linked to surface roughness, which is, in turn, linked to fatigue life. For a given build orientation, there is an optimal range of laser-energy density; outside of this range, internal defects like lack-of-fusion and secondary cracking lead to reductions in total fatigue life. To read more, check out the complete manuscript. This work is supported by an NSF CAREER award (CMMI-1752400) and by the DOD Office of Economic...

Continue readingMachine Learning Model Predicts 3D Crack Path

MMM Lab members, Kyle Pierson and Dr. Aowabin Rahman, implemented a convolutional neural network to predict the growth of a 3D crack surface and to quantify the corresponding model uncertainty. The work was supported by the Air Force Office of Scientific Research Young Investigator Program under Agreement No. FA9550-15-1-0172. Click here to access the full article....

Continue readingWe are now on twitter!

The MMM Lab now has a twitter account. For the latest updates from our lab, follow us @MMMLabUtah. ...

Continue readingKaren’s paper in EFM answers long-standing question

What is the minimum volume requirement for specimens and models to guarantee representative behavior of microstructurally small cracks? Ph.D. student and NDSEG Fellow, Karen DeMille, recently published a paper in Engineering Fracture Mechanics that seeks to answer this very question. She found that the answer depends upon the microstructural arrangement near the crack front as well as the boundary conditions. Her work provides a closed-form approximation for experimentalists and modelers to quickly estimate, under certain assumptions, how much volume would be needed to guarantee that crack-front fields are converged and therefore representative of a crack in a larger structure....

Continue readingIMMI paper on generating grain-resolved foam models

Dr. Joe Tucker (Exponent) and Prof. Spear published a paper recently in the journal Integrating Materials & Manufacturing Innovation (IMMI) that describes a new capability in the widely used software DREAM.3D that allows for generating open-cell, polycrystalline metallic foams. The new capability allows users to generate completely synthetic polycrystalline foam structures, or to overlay synthetic grain structures onto 3D image data of real open-cell foams (for example, from X-ray CT). The plug-in will soon be available free to the public. To read more, click here. The work will appear in a thematic issue of IMMI on 3D Materials Science and is supported by...

Continue reading