Abstract:

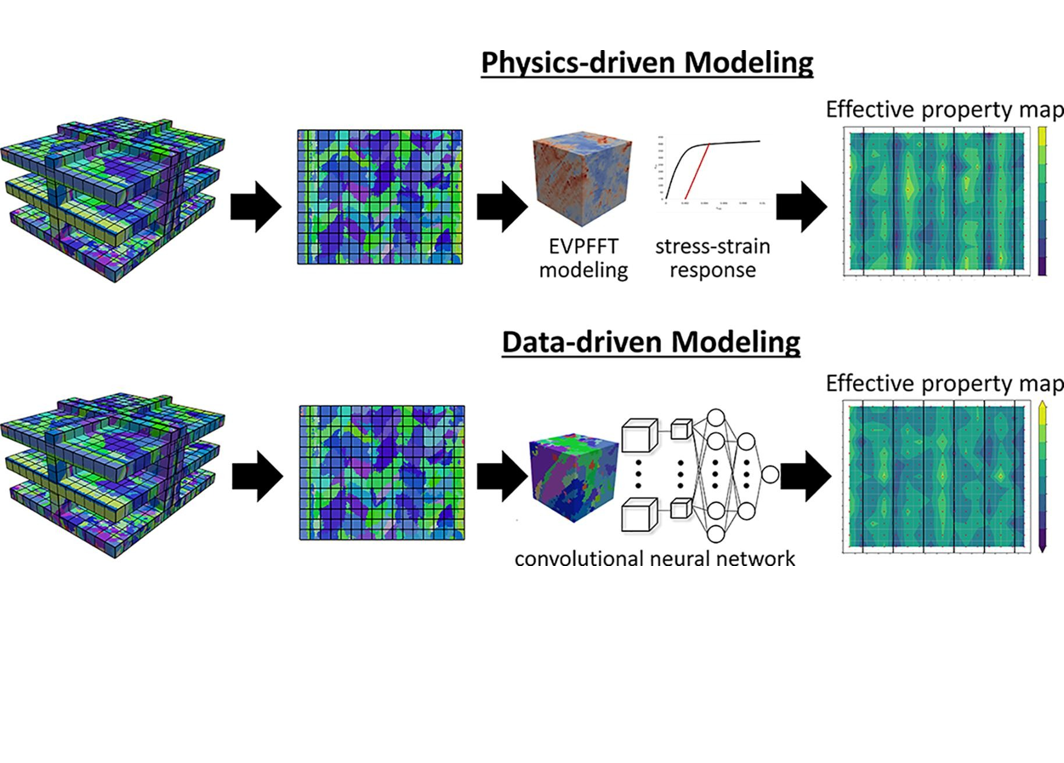

In this work, we investigate the performance of data-driven modeling for mechanical property prediction of a simulated microstructural dataset. The dataset comprises realistic microstructural subvolumes of metal additive-manufactured stainless steel 316L and corresponding effective mechanical properties that were generated with a physics-driven modeling framework. The data-driven models leveraged for this work include Ridge regression, XGBoost, and a custom 3D convolutional neural network (CNN) based on VGGNet. Morphological and crystallographic features describing each microstructure serve as the inputs for the Ridge regression and XGBoost models. The CNN is trained with a 3D image of the microstructure represented by progressively informative input data (ranging from grain ID to crystal orientation, and supplemented with auxiliary features describing the mechanical loading) to determine the relative improvement among different feature types. Comparisons are drawn between the predictive performance of each data-driven model in terms of different scoring metrics and spatial-property maps. The computational efficiency of each data-driven model and the physics-driven modeling framework is also reported. Among all of the data-driven models tested, the CNN models that use crystal orientation as input (with or without auxiliary input features) provide the best predictions, require little pre-processing, and predict spatial-property maps in a matter of seconds.

Authors: Carl Herriott, Ashley Spear

This material is based upon work supported by the U.S. Department of Defense Office of Economic Adjustment under award No. ST1605-19-03. The support and resources from the Center for High Performance Computing at the University of Utah are gratefully acknowledged.

Access article: 2020_Herriott_Spear_CompMatSci